Introducing Eaton MCF-824 Series: The Next Generation of Self-Cleaning Industrial Filtration

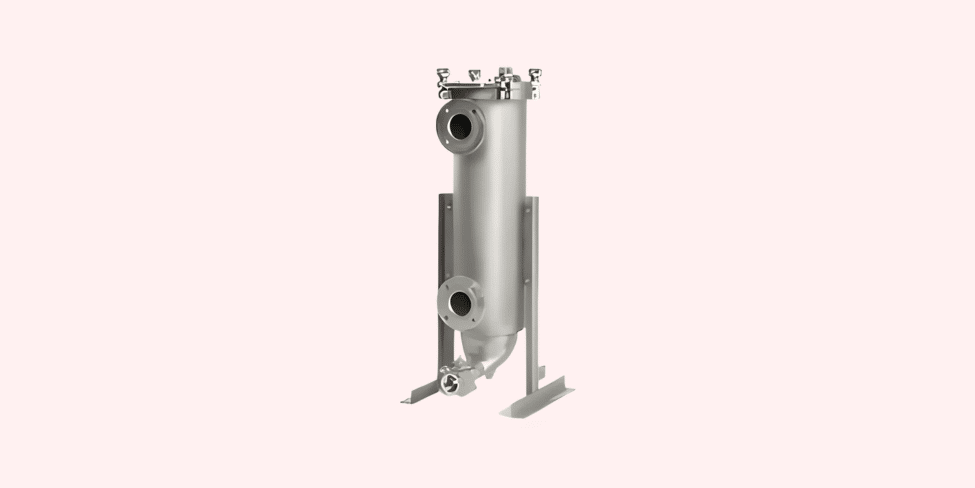

Eaton’s MCF-824 Series Magnetically Coupled Filter brings a new level of reliability and efficiency to industrial liquid filtration. Designed to operate continuously with virtually no downtime, the MCF-824 provides a self-cleaning, permanent-media solution that eliminates the need for external seals and reduces product loss—making it an ideal filtration system for demanding and high-value processes.

With a flow rate of up to 180 GPM, compact footprint, and simplified internal design, this filter combines performance and maintenance efficiency, while supporting both operator safety and environmental compliance.

Key Features and Benefits:

- Self-Cleaning Permanent Media

Reduces operational downtime, eliminates disposable filters, and preserves valuable product during processing. - Magnetically Coupled Drive

Innovative design removes the need for external shafts or seals, eliminating leakage and simplifying cleaning. - Compact Design

18″ x 19.6″ footprint fits in tight spaces with minimal disruption to existing infrastructure. - No Tools Required for Maintenance

Tool-less access to internal components allows for fast service and cleaning. - Versatile Configuration Options

Available with programmable controllers, ASME/CRN design, various elastomers, screen types, and purge configurations. - Safe and Efficient Cleaning Process

Internal cleaning disc powered by rare-earth magnets removes contaminants without interrupting flow or requiring dismantling.

Industry Applications

The MCF-824 is ideal for a wide range of process industries, including:

- Food & Beverage

Chocolate, edible oils, starch, hot fry oils, and curtain coaters - Chemical & Petrochemical

Phenolic resins, petroleum-based greases, adhesives, detergents - Pulp & Paper

Paper coatings, PCC/GCC slurries, lime slurries - Pharmaceuticals & Nutraceuticals

Nutraceutical liquids, CIP fluids (sodium hydroxide), ethanol processing - Paints, Inks & Coatings

Paint, ink, and pigment slurries - Metalworking & Machining

Machining coolants and cutting fluids - Tallow and Animal Fat Processing

Use Case Spotlight: Improving Uptime in Chocolate Production

Q: How does the MCF-824 help reduce product loss and improve cleaning efficiency in a chocolate manufacturing plant?

A: A major confectionery producer faced frequent filter changeouts and chocolate losses during sanitation procedures using traditional bag filters. After installing the MCF-824, the company saw:

- Immediate reduction in product waste due to the permanent media system.

- Elimination of costly downtime, as the filter operates continuously—even during cleaning cycles.

- Faster, safer maintenance with no tools needed and no filter replacement costs.

- Cleaner final product with fewer contaminants and more consistent flow through production lines.

By switching to the MCF-824, the manufacturer saved thousands of dollars per year in material loss, reduced labor hours for filter maintenance, and significantly improved production line uptime—all without compromising product quality.

Ready to Upgrade Your Filtration Process?

Eaton’s MCF-824 is redefining self-cleaning filtration. With unmatched uptime, a compact footprint, and powerful cleaning technology, it’s the perfect fit for modern industrial operations.

📞 Contact Us Today

PT. Flow Force Engineering

The Kensington Office Tower Unit C2, 3rd Floor, Jln. Boulevard Raya, No. 1 in North Jakarta

📞 +62 81188027059| 📧 sales@flowforceengineering.com

🌐 www.flow-force.com