Our Services

Scope of Supply

At Flow Force Engineering, our supply scope covers a wide array of products and services crafted to address the varied requirements of clients within liquid handling and processing.

We deliver customized solutions featuring premium equipment, advanced technologies, and essential consumable items—backed by our professional know-how and dedication to quality.

Each solution is thoughtfully selected to guarantee consistent performance, operational efficiency, and adherence to global standards, ensuring our clients achieve optimal safety and excellence in their operations.

Our Service Offerings

Explore tailored solutions across filtration, vacuum systems, homogenisers, dosing pumps, and liquid handling — all designed to maximize efficiency and reliability.

Filtration Services

We Provide Value-Added Services to Support Your Filtration Needs:

- Filtration System Consultation & Product Selection Our team offers expert guidance in selecting the most suitable Eaton filtration products — including bag filters, cartridge filters, strainers, and housings — tailored to your process requirements and industry standards.

- Customized Filtration Solutions We collaborate with customers to design customized filtration setups using Eaton’s advanced technologies, ensuring efficiency, compliance, and performance across various applications such as food & beverage, pharmaceuticals, chemicals, and water treatment.

- Installation Support & Commissioning We assist in system setup and integration, ensuring that Eaton filtration systems are properly installed, commissioned, and calibrated for optimal operation.

- After-Sales Support & Technical Assistance Our service doesn’t stop at delivery. We provide reliable technical support, troubleshooting, and coordination with Eaton for any product-related issues or warranty claims.

- Maintenance Services & Filter Replacement Planning We offer scheduled maintenance services, including filter change-out planning, to ensure continuous operation, reduce downtime, and maintain filtration performance.

- Access to Genuine Eaton Spare Parts & Consumables We supply original Eaton filter bags, cartridges, and spare parts to ensure the longevity and reliability of your filtration systems.

- Training and Process Optimization We provide on-site or virtual training for operators and maintenance teams, along with recommendations to improve system performance and reduce operational costs using Eaton’s filtration technologies.

Vacuum Cleaner Services

We Provide Comprehensive Solutions to Support Your Central Vacuum Needs:

- Project Consultation & System Design We support customers with detailed assessments and tailored system design, ensuring the Disan vacuum system matches the layout, capacity, and specific requirements of your facility.

- Customized Central Vacuum Solutions Based on your industry (e.g., food, pharmaceuticals, metalworking, plastics), we offer customized solutions using Disan’s modular and scalable systems for optimal dust and debris collection.

- Installation Guidance & Technical Support Our technical team assists in system layout planning, pipe network design, and on-site installation guidance to ensure proper configuration and maximum suction performance.

- After-Sales Service & Maintenance Plans We provide ongoing support including preventive maintenance services, troubleshooting, and timely technical assistance to ensure your Disan system operates at peak efficiency.

- Supply of Genuine Spare Parts & Accessories We deliver original Disan components, including filters, motors, and accessories, ensuring durability, performance, and compliance with Disan specifications.

- System Upgrades & Expansion Support Whether you need to expand your vacuum system or improve its performance, we offer upgrade options using the latest Disan technology and components.

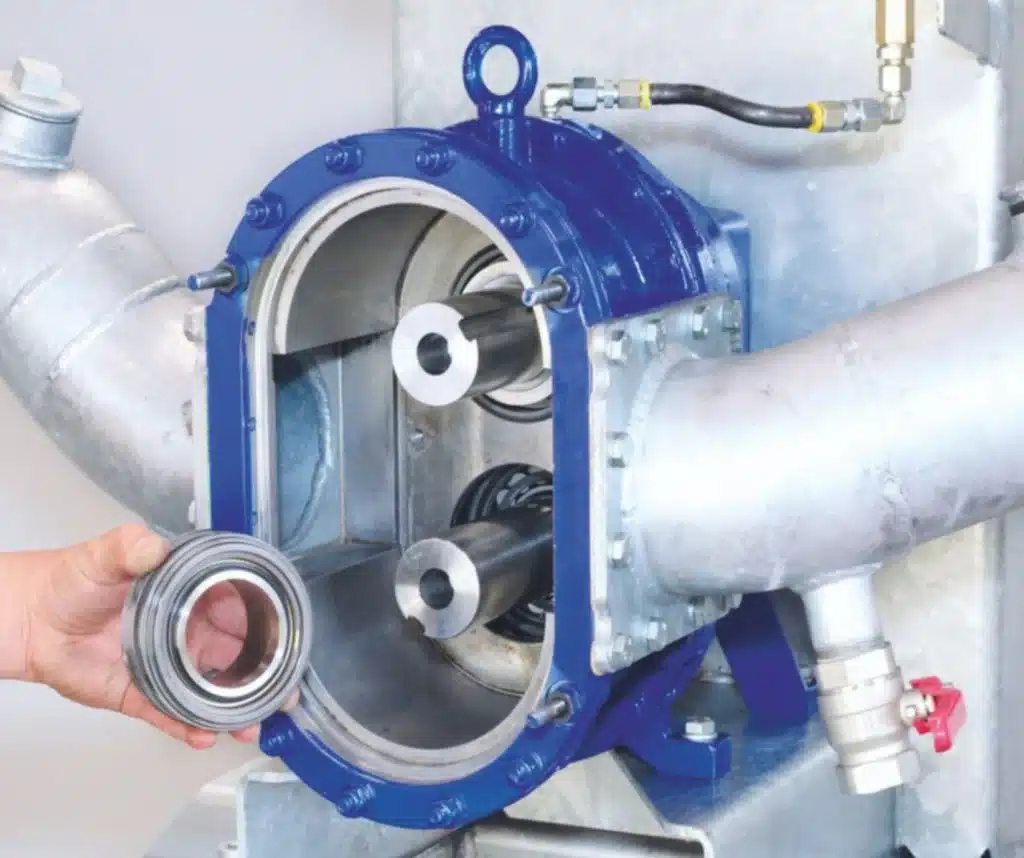

Homogeniers Services

We provide machines and spare parts, and also the expertise to maximise their productivity. Our services include:

- Training & knowledge transfer

- Maintenance

- Repairs

- Overhauls, examples of which include:

- Conversion from manual to hydraulic operated homogenizers valves

- Conversion from “conventional” to energy saving micro gap type homogenizing valves

- Conversion of the cylinder block from poppet to ball valve type

- Automatic control of the homogenizing pressures

- Conversion of standard cylinder blocks to double packed aseptic execution

- Complete overhaul of machines and cylinder blocks

Dosing Pump Services

We help customers select the ideal Doseuro metering pump based on chemical properties,

flow rate, pressure requirements, and process conditions, ensuring accurate and efficient dosing performance.

- Application Consultation & Pump Selection

We help customers select the ideal Doseuro metering pump based on chemical properties,

flow rate, pressure requirements, and process conditions, ensuring accurate and efficient dosing performance. - Customized Dosing Solutions

Whether for water treatment, chemical processing, or industrial manufacturing, we offer

customized pump configurations and system integration using Doseuro’s versatile product range

(plunger, diaphragm, and hydraulic pumps). - Installation Support & System Integration

Our technical team provides support for proper pump installation, alignment, and integration

into your existing process control systems to ensure optimal and safe operation. - After-Sales Technical Support & Troubleshooting

We offer responsive after-sales service including diagnostics, repair recommendations, and coordination

with Doseuro for warranty matters or component replacements. - Preventive Maintenance & Calibration Services

Regular maintenance, performance checks, and dosing calibration are provided to ensure dosing

accuracy and to reduce unexpected downtime in critical applications. - Supply of Original Spare Parts & Accessories

We ensure the availability of genuine Doseuro spare parts and accessories, including diaphragms,

valves, seals, and pump heads, to maintain long-term reliability.

Dosing Pump Services

- Process Consultation & System Configuration

We support customers in evaluating their process requirements and designing tailored IDMC liquid

handling solutions, including CIP systems, mixing tanks, transfer systems, and flow control units —

ensuring compliance with hygiene and industry standards. - Customized Engineering Solutions

Based on your application — dairy, food & beverage, pharmaceuticals, or biotech — we offer

integrated solutions using IDMC’s proven technology for precise flow control, mixing, transfer,

and storage of liquids. - Installation Supervision & Commissioning Support

Our team provides on-site support during installation and commissioning to ensure that IDMC systems

are properly set up, tested, and validated for immediate operation. - After-Sales Service & Preventive Maintenance

We offer full after-sales support, including troubleshooting, regular maintenance schedules, and

condition-based servicing to reduce downtime and maximize equipment reliability. - Supply of Genuine Spare Parts & Components

We ensure quick and reliable access to original IDMC spare parts such as valves, pumps, seals,

instruments, and fittings to maintain your system’s efficiency and safety. - System Upgrade & Retrofit Support

We assist in upgrading or expanding existing liquid handling systems by integrating new IDMC components

or modules, aligned with process improvements and capacity enhancements. - Operator Training & Technical Documentation

We provide technical training and complete documentation to your operations and maintenance teams,

enabling safe, compliant, and efficient usage of all IDMC systems.